Measuring chip moisture faster with accuracy

Sun Paper buys wood chips by the truck load for paper production in its alkaline peroxide mechanical pulp (APMP) line at its mill in Yanzhou city, Shandong province. As chips are bought by dry weight, the moisture content of each truck load is critical to the purchasing settlement. Since June 2019, the moisture measurements have been performed by the Valmet MR Moisture Analyzer (Valmet MR).

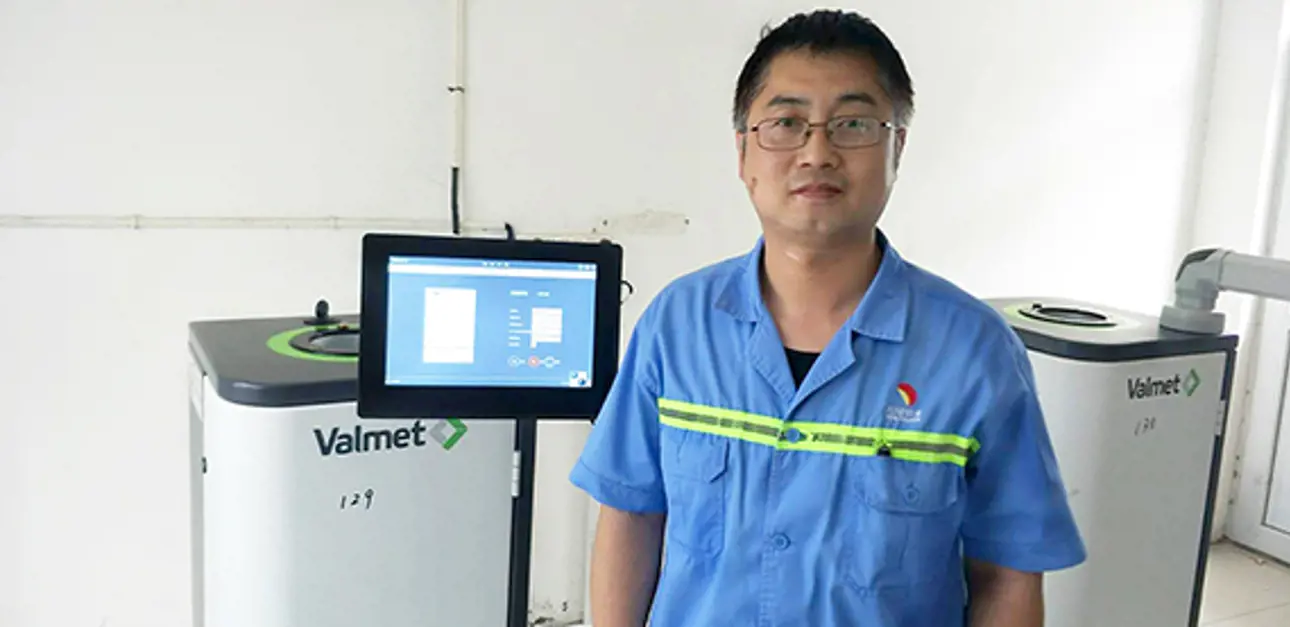

Valmet MR helps us to increase measurement capacity and speed, lower the safety risk and decrease human error with chip moisture result data uploaded to mill system real time.

Poor measurement efficiency

With an average of 150 trucks a day and at peak times up to 400, the traditional laboratory measurement was tedious, time-consuming, and prone to operator error. “Before using the moisture analyzer, ovens were used to dry the wood chips to measure the moisture. There are a total of 11 ovens in the laboratory to meet the measurement needs at peak times,” says APMP Wood Chip Workshop Manager, Mr. Fang Zhongguan. Due to the high temperature of the oven, the large power consumption, and personnel required, the efficiency of the process was poor. “An additional problem was the long measurement time, it usually took 6-8 hours to measure one batch in one oven. The power of each oven is 4KW, so the daily power consumption was also very large and posed a safety risk.”

Magnetic Resonance solution

The Valmet MR is a unique device that has set a new standard for efficient moisture analysis. Using Magnetic Resonance (MR) technology it measures water content by measuring hydrogen atoms from free water molecules. Requiring no special sample preparation, a sample container is filled with chips and placed in the unit which then weighs the sample and measures the moisture content. After two minutes, the result is available on the screen and uploaded to the mill system. “Easy calibration and low maintenance are also big advantages,” adds Fang.

Faster results

“Using the Valmet MR Moisture Analyzer greatly improves the measurement speed and avoids artificial interference factors as well as reducing the labor load. It is easy to complete the measurement needs even during the peak hours,” says Fang. Earlier measurements were made with several samples from each truck mixed to one weighed sample which was then oven-dried. It is now possible to measure more samples separately for a more accurate average result for each load.

Accurate and reliable

For Li, working with Valmet has been positive, “Valmet‘s technology is very advanced, and their service is very professional. Cooperation with Valmet has been a very nice experience. The measurement results are very accurate and reliable, helping to increase our work efficiency, and fully match our requirements for chip moisture measurement,” he declares.

Information about the customer Sun Paper

Sun Paper is one of the subsidiaries of Shandong Sun Holdings Group, which was founded in 1982. Currently Sun Paper has two mills in China’s Shandong province with around 4 million tonnes/year of paper and board capacity and 1.3 million tonnes/year of wood pulp capacity. The company also operates a mill in Laos with a 300,000 tonnes/year dissolving pulp line and a 400,000 tonnes/year recycled pulp line. In July 2019, Sun Paper established a wholly-owned subsidiary, Guangxi Sun Paper, to build an integrated pulp and paper mill in Beihai.

Sun Paper has recently ordered 2 additional Valmet MR analyzers, one to the Yanzhou mill and the second to the Yandian mill. This brings the total to six Valmet MR Moisture Analyzers in different mills at Sun Paper.