Instant productivity boost with IQ Steam Profiler

Naini Papers Ltd, an integrated pulp and paper mill, is one of the few premier paper manufacturing facilities in India. Producing writing and printing paper from agricultural residue bagasse and wheat straw, the mill has always been ready to implement the latest available technologies to optimize production costs and keep quality on target. In 2019 the mill invested in a Valmet IQ Steam Profiler to improve moisture profiles and provide steam savings while increasing the average moisture content of the paper and delivering better sheet quality. The results have been impressive - the return on investment was less than 1 year. The customer has been able to increase production while gaining significant savings in steam and fiber.

The results were seen immediately, the desired improvement in product quality was visible. Our Operators have become so confident about the steam profiler that they don’t want to switch it off.

Mr. Pawan Agarwal

Managing Director, Naini Group

Direct savings in steam - under 1 year payback time

The Valmet IQ Steam Profiler is a high technology multi-zone steam box providing unique profiling accuracy for the forming and press sections of paper and pulp machines. At Naini Papers, the installation location is on the wire section above the Trivac suction box to heat the sheet by 20° C prior to the press. By heating the water in the sheet, its viscosity is lowered allowing it to drain more readily and reduce moisture entering the pulp dryer.

The advanced steam injection technology employed by the IQ Steam Profiler maximizes steam absorption efficiency and its electromechanical actuators with position feedback provide high-performance profiling capabilities. Dryness after the couch has increased significantly which translates directly to savings in steam consumption.

Mr. Pawan Agarwal, Managing Director of Naini Group, who is well known for his continuous drive to implement the latest available technologies in the mill, says: "The results were seen immediately, the desired improvement in product quality was visible."

"The biggest benefit with IQ Steam Profiler was improved product quality with respect to even moisture profile. Our Operators have become so confident about the steam profiler that they don’t want to switch it off." Mr. Pawan Agarwal further added.

Steam consumption reduced 0.1mt/mt right after the installation of the IQ Steam Profiler.

| Results | ||

|

Project Targets |

Before |

After |

|

Moisture at pope reel |

3.20% |

4.20% |

|

”Two sigma values” of moisture |

0.9 to 1.2 (@ 3.7%moisture) |

0.5 to 0.6 (@ % 4.2% moisture) |

|

Smoothness (NSS grade) |

198/230 ml/min |

172/200 ml/min |

|

Smoothness (SS grade) |

195/225 ml/min |

175/200 ml/min |

|

Two sidedness |

30-32 ml/min |

25-27 ml/min |

|

Overall Product quality |

Improved |

“We think the steam box technology supplied by Valmet is world-class and well supported by the team Valmet.”

Quality improved to the target level

Higher average dryness provides the room for moisture profile control. Prior to installation, an uneven moisture profile from the press, with one side of the sheet drier than the other, made it difficult to achieve moisture targets at the reel. The IQ Steam Profiler with 40 controlled zones across the sheet has enabled an increase of moisture at the pope reel from 3.2% to 4.2% with a significant improvement in 2 Sigma profile values.

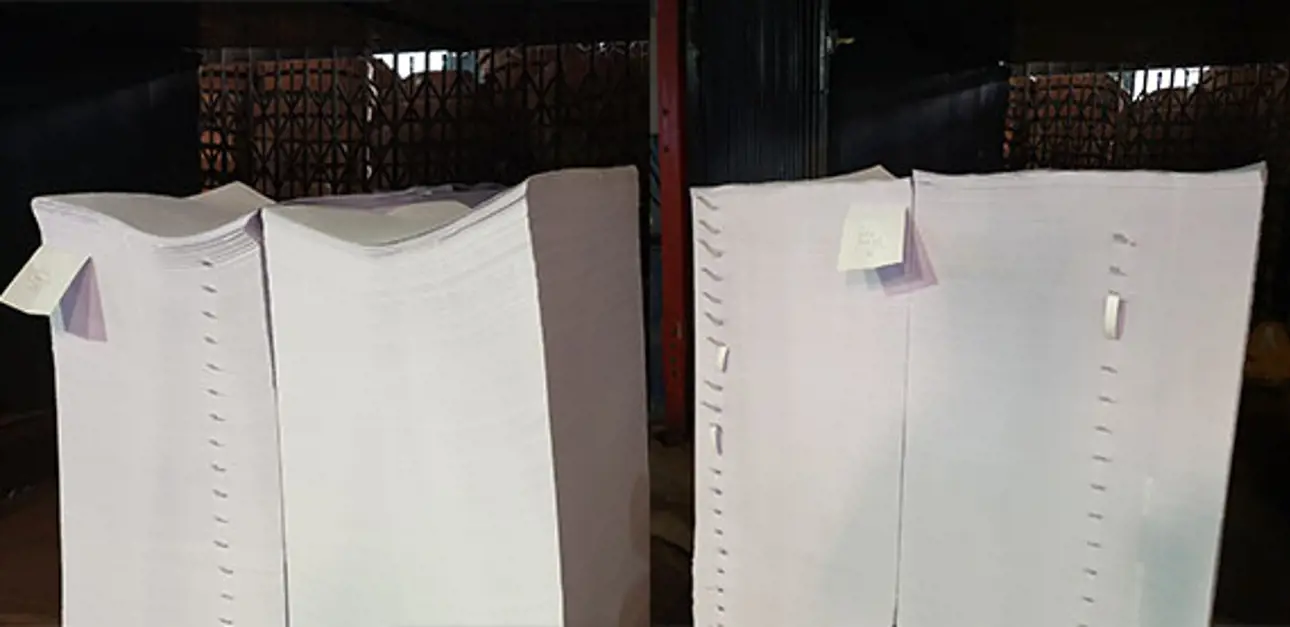

Since the successful summer 2019 startup, mill project objectives and Valmet’s performance guarantees have been met. Savings and quality are both on target with together with more uniform reel buildup and warp-free stacking of cut sheets. Discussions are already underway for another IQ Steam Profiler for Naini’s second machine at Naini Tissues Ltd., which also makes writing and printing paper from agricultural residue, mainly bagasse and wheat straw. Both machines already have Valmet IQ quality management and control systems, which together with the latest investment show Naini Group’s confidence in Valmet, a constructive and profitable partnership for both companies.

“We think the steam box technology supplied by Valmet is world-class and well supported by the team Valmet”, says the production team from Naini Papers.

For more information, please contact:

Toni Räty, Product manager Rakesh Uniyal, Sales Manager, India

toni.raty(at)valmet.com rakesh.uniyal(at)valmet.com