Energie AG Umwelt Service in Austria optimizes its district heating network successfully with Valmet DNA Advanced Process Control

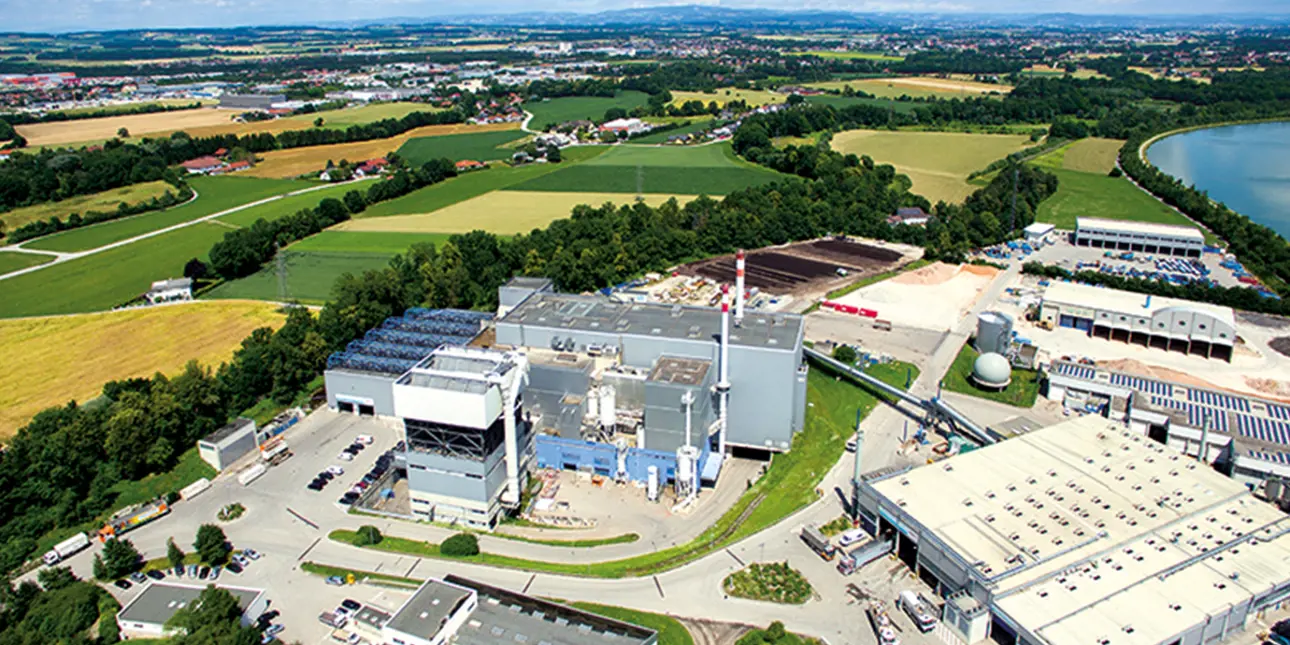

Valmet has delivered a multi-part district heating automation project to Energie AG Umwelt Service waste recycling plant and municipal district heating plant in Wels, Austria. Building on long-term collaboration between Energie AG Umwelt Service and Valmet, the project aimed to boost sustainability by switching Energie AG Umwelt Service’s two incineration lines to waste heat to supply the surrounding community.

Long-term sustainability for the Wels region

Since 1991, Energie AG Umwelt Service has been operating the waste treatment plant in Wels, processing over 300,000 tons of residual waste annually with its two incineration lines. The plant supplies 100% of the district heating for the Wels community and covers the needs of 14,800 households and numerous businesses.

In 2005 and 2006, Energie AG Umwelt Service selected the Valmet DNA Automation System for both its existing WAV I waste incineration plant and its new WAV II incineration line. In 2017, EAG optimized its boiler with Valmet DNA Combustion Manager.

The district heating optimization project in 2021–2023 was one of the four district heating subprojects delivered to Energie AG Umwelt Service by Valmet. Another involved extending the existing Valmet DNA Automation System to optimize district heating operations within the waste treatment plant.

The largest subproject replaced a third-party district heating distributed control system with a Valmet one featuring approximately 700 I/Os, an ACN cabinet and applications. The final subproject was a new DCS for the district heating plant’s two hot water boilers with an I/O cabinet and applications.

Valmet has delivered a multi-part district heating automation project to Energie AG Umwelt Service’s waste recycling plant and municipal district heating plant in Wels, Austria. From left to right in the facility's control room: Andreas Geiblinger (Process Engineer), Günther Gruber (Power Plant Manager), and Bashkim Iseni (Operator).

Switching from burning fossil fuels to 100% waste

The successful Energie AG Umwelt Service project makes Wels more sustainable and efficient while securing its heat and energy supply. Today, the gas-powered plant for district heating has been completely shut down. Only waste is now used to heat the entire city," says Power Plant Manager Günther Gruber from Energie AG Umwelt Service.

“We contribute to our area’s climate protection by recycling waste,” says Günther. “Using heat from Energie AG Umwelt Service’s waste treatment plant is an ecological and economical way to supply heat to Wels. It supports our commitment to a circular economy. This provides enormous potential to reduce CO2 emissions. Just one household that switches from fossil to waste for district heating can save up to 2,280 kg of CO2 per year. This corresponds to the binding capacity of 182 large trees,” he says.

“Contributing to climate protection, improving the quality of life and utilizing synergies are the goals of Energie AG Umwelt Service its network partners, EWW AG and Wels Strom GmbH. The companies’ collective focus is on advancing the region’s heat and energy supply to make Wels even more sustainable, efficient and safe,” Günther highlights.

In the picture from left to right Andreas Schön from Valmet and Dino Bojicic (Process Engineer).

Proven district heating optimization

Valmet already has a proven track record at the plant with its Valmet DNA Distributed Control System (DCS), Valmet DNA turbine control system, Valmet DNA Combustion Manager and Valmet DNA District Heating Manager.

Valmet’s comprehensive industry portfolio, complete process solutions and high technical standards met our quality requirements. But the biggest factor was our previous 18 years of trust and collaboration with Valmet,” Günther says.

Mustafa Began, Service Area Manager from Valmet, agrees. Good trust has built up between our two companies over the years, and Energie AG Umwelt Service has been extremely satisfied with our projects. We are continuing to provide them with advanced automation solutions and a wide range of lifecycle services for their two waste incineration lines.”

All rebuild work was carried out in the running system and completed in only a few weeks. “There was no need to shut down. We were able to change from supplying 10% to 100% in very short time,” Mustafa continues.

In the picture from left to right: Bashkim Iseni, (Operator), and Dino Bojicic (Process Engineer).

Valmet DNA District Heating Manager is an Advanced Process Control (APC) application based on the Valmet DNA Automation System. The solution already has a proven track record in many cities in Finland. It offers economical and operational optimization of heat production and delivery. The application includes all available online forecasts and information to optimally control all units and conditions for a district heating system. The solution supervises and regulates the entire network, ensuring that heat consumption and production are always in balance.

Energy system flexibility and the circular economy

The Wels project showcases Valmet’s ability to supply customers with future-ready flexibility in their energy systems.

Energy systems are becoming increasingly complex due to the growing integration of renewable energy sources and energy efficiency solutions, such as heat storages or heat pump plants. Valmet’s advanced solution, seamlessly integrated with plant automation and various external systems, enables global economic and carbon neutrality optimization and maximizes overall energy system flexibility,” says Tiina Stenvik, Director, Performance Solutions, Valmet.

“Energie AG Umwelt Service has taken two major steps toward this flexibility. They have DNA Combustion Manager in the boiler, and now they have DNA District Heating Manager in the district heating network,” she continues.

The plant’s automation expansion allows Energie AG Umwelt Service to meet the increasing demand for waste heat in Wels. Moreover, it fulfills the sustainability goals of the company. Wels now sets a new benchmark outside of Finland with its flexible energy system and support for the circular economy by using waste as a valuable resource in district heating.

In early 2024, Energie AG Umwelt Service ordered steam turbine automation from Valmet. This will further enhance the city’s energy efficiency and sustainability initiatives.

For more information, please contact:

Mustafa Began, Valmet

Mustafa.began(at)valmet.com