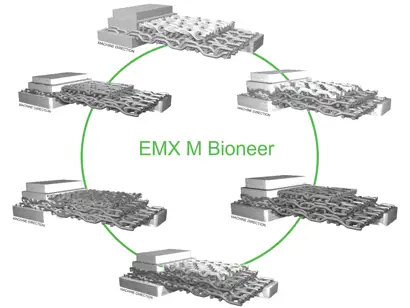

Press felt with excellent runnability and reduced carbon footprint

Valmet Press Felt EMX M Bioneer for board machines

Valmet Press Felt EMX M Bioneer’s modular design ensures sufficient dewatering capacity throughout the felt’s lifetime, and the smooth paper-side of the fabric delivers excellent sheet quality for the targeted grade. Additionally, the felt’s raw material includes partially bio-based yarn with lower CO2 emissions compared to traditional yarn, thereby reducing the felt’s carbon footprint.

Long lifetime and stable running

Enough water handling capacity – no crushing

Optimal structure against roll, belt and felt marking

Raw materials with lower CO2 emissions

Looking for immediate climate actions?

Here you have a quick win: Valmet Press Felt EMX M Bioneer with reduced carbon footprint. Valmet is pioneering the use of bio-based raw materials in paper machine clothing production. In Valmet Press Felt EMX M Bioneer, part of the fossil raw material has been replaced by a bio-based alternative, thereby reducing the felt's carbon footprint.

Watch the video and learn more!

This is Valmet Press Felt EMX M Bioneer

Valmet Press Felt EMX M Bioneer is a laminated modular felt with combined twisted and monofilament yarns, especially designed for board machines. Its base structure is easily adjustable. The felt features high compaction resistance and CMD stability. The structure is very durable and optimal against wrinkles and marking.

Additionally, part of the felt’s fossil raw material is replaced with a bio-based alternative, thereby reducing the felt’s carbon footprint.

ISCC PLUS ensures a transparent and traceable supply chain of raw material

Our production unit in Tampere, Finland, has earned the International Sustainability and Carbon Certification (ISCC), enabling the use of bio-based raw material in press felt production using the mass balance approach.

The certification shows that our production prosess is well-structured and thoroughly documented, ensuring easy traceability of raw material throughout the entire supply chain. The certification needs to be renewed every year.

What does mass balance approach mean?

Mass balance approach is a proven methodology to trace the raw materials in a product’s value chain. At Valmet, we use a distinct accounting method to verify that the bio-based raw material has replaced an equivalent quality of fossil raw material at the beginning of the supply chain and can be attributed to the press felts, ensuring that both input and output are balanced.

In practice, the raw materials such as forestry residuals and used cooking oil are broken into monomers (basic organic chemicals) having identical characteristics with fossil monomers. When processed into polymers and further to yarns and fibers, their characteristics remain the same – meaning it’s impossible to distinguish between bio-based and fossil materials in the end product.

Let’s start today!

We will scale up the proportion of bio-based raw materials in Valmet Press Felt EMX M Bioneer continually. To begin with, the proportion of bio-based raw material is ten percent, but it can be scaled up to 100 percent.

This gives you a choice. How much do you want to reduce the carbon footprint of your press felt?

Want to join the ranks of satisfied Valmet press felt customers?

Start the discussion with our fabrics experts for more information.

Contact usRelated articles