Functional film sizing and coating color application

OptiSizer Film

OptiSizer Film and its functional and innovative design provides excellent runnability. The design of OptiSizer Film has evolved for simple and reliable solutions resulting in easy operation and installation and fast initial start-up, which also makes it the perfect choice for rebuild projects. Multiple production and speed world records set on a number of production lines serve as the best evidence of OptiSizer Film’s capabilities.

High quality sizing

Steep start-up curve

Easy maintenance and operation

High process know-how and many references

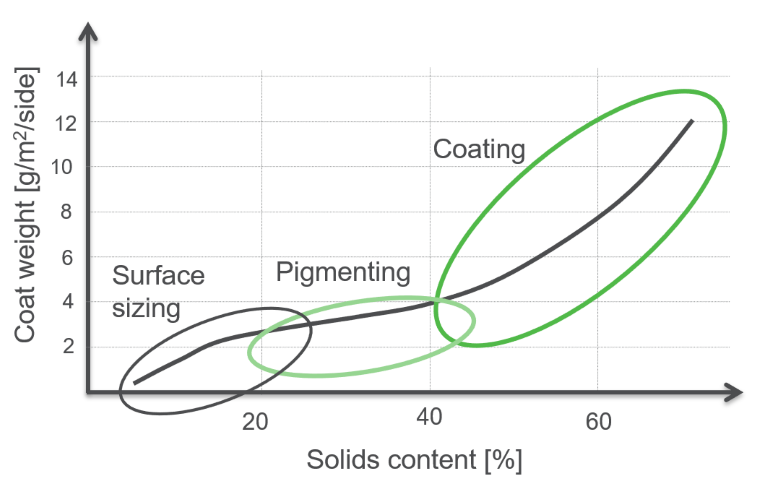

A thin film of size or coating color is applied to the surface of an applicator roll. Simultaneous application on both sides of the sheet also saves space, which provides a competitive advantage in the case of high-capacity investments. The film is transferred to both sides of the paper sheet in a nip formed between two transfer rolls.

Want to talk to our sizing experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsHigh quality sizing and raw material savings

Valmet's advanced film application method uses a unique, patented perforated sealing blade to minimize feed and return flow and for low circulating volumes. It eliminates harmful flow disturbances and air entrainment even at high speeds, and the flexible sealing blade tolerates well wrap breaks and is easy to change. This leads directly to high quality sizing.

Film sizing offers raw material savings potential due to increased z-strength and stiffness. It applies a starch layer that also binds the surface and fills pores, improving the holdout of coating color. The film application method means that the starch applied contains less water compared to pond sizing, helping to minimize the swelling of fiber flocks in the middle ply.

Film sizing also flattens the surface topography before coating. This, combined with better coating holdout, enables reduced of coat weight and lessens the need for calendering.

High-quality components are keys to excellent CD profiles. The composite structure of the application beam means that:

- Coefficient of heat expansion is low

- There is no need for water circulation

- There is no need for maintenance

- And, the temperature variations of the color or size have no effect on beam straightness

Wide application area

Steep start-up curve

Steep start-up curve is a must for each project from a smaller improvement toa complete line installation. Full workshop pretesting is one of the key elements to make sure that everything is in order when the start-up takes place. Valmets sizers are fully equipped and easy to operate. You will have a professional Valmet team to support you all the way.

Easy maintenance and operation

Valmet's sizers are easy to operate. The nip loads are precise and sizer application beam is easy to adjust. The controls are very versatile to fulfill all the requirements set for sizing.

Process know-how & references

As for all Valmet's projects, you will have an experienced project personnel from Valmet to support your investment project. You will also get sizing process optimization support from Valmet.

Valmet's deep knowledge about projects and paper machine processes come from the numerous deliveries and references.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookLearn more about the services and automation solutions for sizing

Explore our latest board and paper press releases

- Dec 19, 2025Muoto products produced with Valmet 3D Fiber technology piloted at Valmet’s Jyväskylä location

- Dec 8, 2025Valmet has completed change negotiations for temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Nov 26, 2025Valmet supports Wuzhou Special Paper’s transition to recycled board grades with a complete paper machine conversion rebuild

- Nov 5, 2025Valmet to start change negotiations regarding temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies