OptiPress Center

Proven center-roll based press section for lighter grades

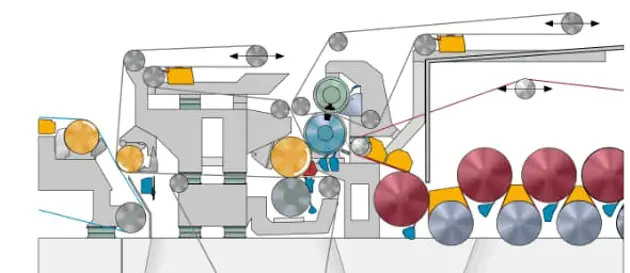

OptiPress Center – center roll based press section - is a reliable, well-known concept that combines close to 40 years of pressing technology experience with modern shoe press technology. With this solution, a shoe press replaces a roll just before the first open draw. The resulting boost in dryness thus fully benefits web runnability in the open draw. If necessary to meet end quality requirements, a center-roll based press can be followed by a separate roll press. In the containerboard production from recycled fiber, machines dedicated to high speeds and light basis weights can be equipped with an OptiPress Center pressing process.

High dryness and good moisture profiles

Compact design and easy to apply also in rebuilds

A reliable concept with numerous references

Added capacity potential in rebuilds

Notable track record of center press deliveries

There are hundreds of outstanding Valmet OptiPress Center (formerly named as SymPress) press sections operating successfully around the world in paper and containerboard production machines – for new lines and rebuilds alike. Read more about some of these customer success stories here.

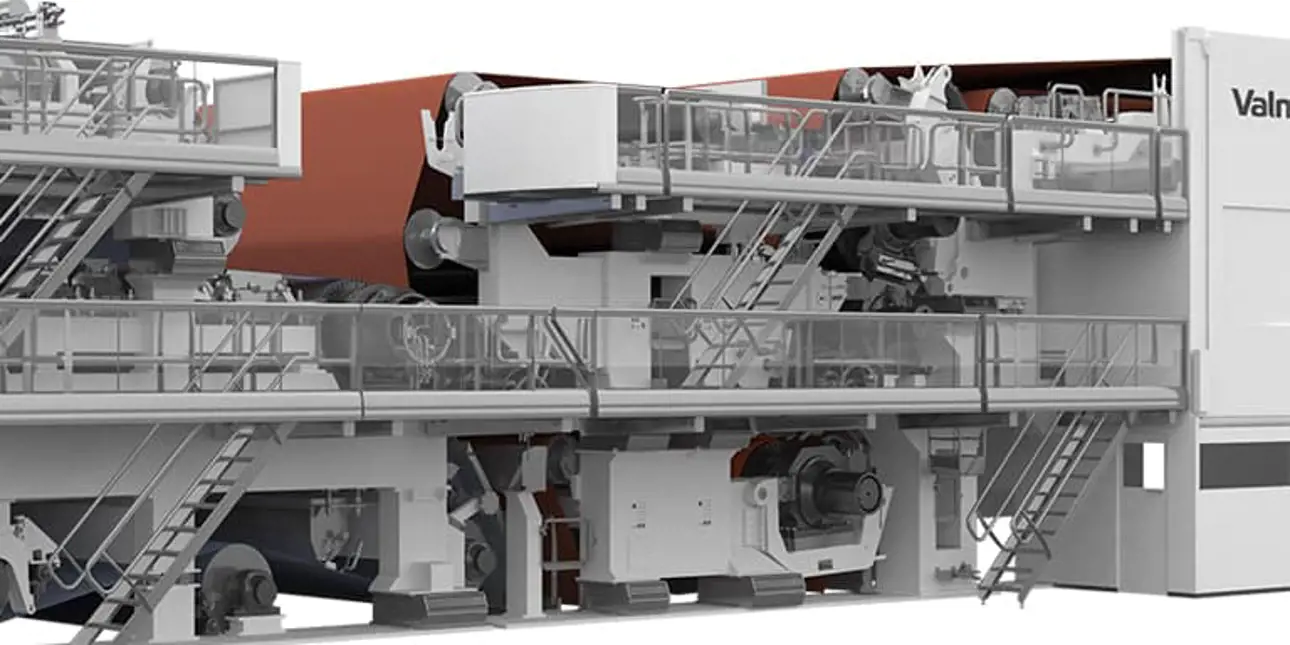

OptiPress Center center-roll based press section

Innovation in center press: Closed sheet transfer with OptiPress Center

Transfer belt technology allows the draw between the press and dryer sections to be closed in center roll-based concepts, too. Less draw is required, and dryness and end product qualities, such as strength and porosity, improve. Rather than a transfer belt, it is also possible to use a smooth, heated metal belt that goes around the center roll and guide stretcher roll, This metal belt technology further improves press section performance, as the increased temperature of the paper web enhances dewatering in the press nip.

Want to talk to our press section experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsLooking for press felts and fabrics?

Valmet press felts are always tailor-made to the specifications of each individual paper machine and position: paper grade, furnish, speed, dimensions. With proven world class technology of press felts, the web transfers smoothly to drying section with high dry content and superior quality values.

Read morePlanning a press section rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookLooking for press roll covers?

Roll covers in the press section have a strong impact on production line efficiency, capacity and product quality. Along with press section clothing, they are key components for dewatering through the wet pressing process. Especially in center roll-based presses with an open draw, roll covers also directly affect machine runnability.

Read moreExplore our latest board and paper press releases

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States