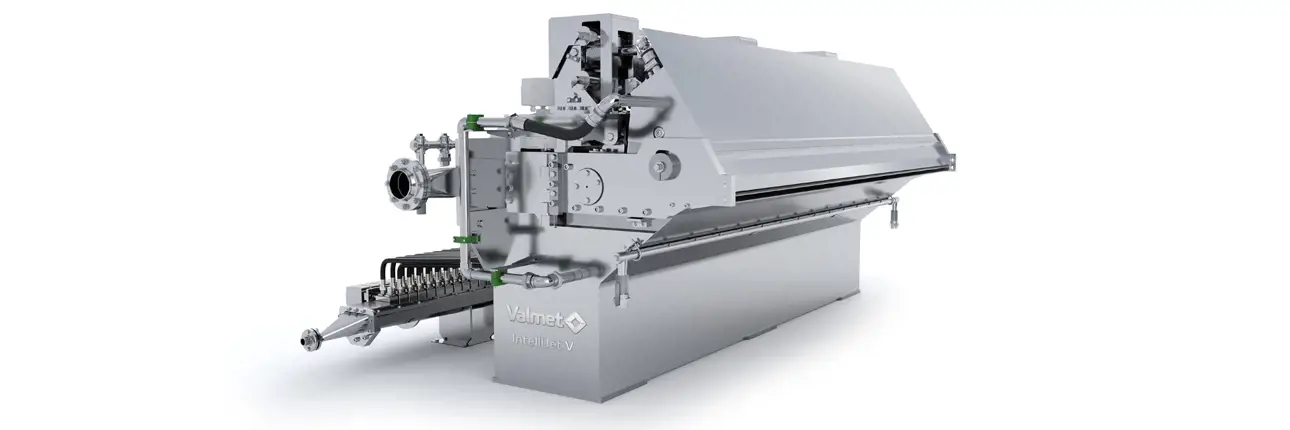

IntelliJet V headbox

An intelligent solution for smart paper production

Every feature of the IntelliJet V is meticulously crafted to enhance the papermaking process, optimizing efficiency and productivity. Advanced customization options are one of the headbox’s key features. Our team of experienced engineers are able to tailor the IntelliJet V to specific customers’ requirements, ensuring seamless integration into papermaking operations.

High CD Profiles Uniformity and Production Stability

Excellent Sheet Formation and High Controllability

High Reliability & Operators Friendly Design

Excellent quality and sheet formation

High CD Profile Uniformity

High CD profile uniformity is achieved due to high quality manufacturing including laser welding and electropolishing. In addition, design features such as a parabolic header, in-line tube bank and dilution control help ensure excellent CD profiles.

Production Stability

Production stability is thanks to a fully hydraulic system and optimized turbulence out of the tube bank. The IntelliJet V can be paired with either a horizontal or vertical pulsation attenuator to minimize any MD disturbances created upstream of the headbox.

Excellent Sheet Formation

A high head loss tube bank design, divider sheets & optimized nozzle geometry maintain the highest level of sheet formation.

High Controllability

Header pressure balancing, edge flow controls and deckle boards allow control of fiber orientation. Additionally, slice lip profiling, jet geometry control, thermal stabilization and a dilution control system help to optimize and ensure cross direction profile stability. The IntelliJet V design provides headbox stability even at high pressures.

Clean Operation

Proper design of the entire headbox supply system from the header through the nozzle, including high nozzle velocities, superior surface smoothness and electropolishing, allow for clean operation.

High Reliability & Operator Friendly Design

Good access to the interior of the headbox is thanks to a pivoting cross machine header and pondsides that open past 90 degrees. A central lubrication panel assures easy maintenance.

How do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookLooking for headbox related services?

We provide a wide range of professional headbox maintenance and testing services to get the best out of your headbox. These services make it possible to eliminate web streakiness and jet inaccuracy, to lower the need for slice opening adjustments, and to improve dry weight profiles.

Go to headbox servicesExplore our latest board and paper press releases

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States