Leading technology for superior runnability and maximal web stability

Runnability Systems

Runnability systems stabilize the run of the web and secure tail threading in the dryer section. In practice, the equipment helps to hold the web in contact with the fabric by creating underpressure on the other side of the fabric. The underpressure is created by blowing, suction, or a combination of both.

Maximal web stability

Machine speed increase

Less breaks

Secured tail threading

Maximal web stability with Valmet Runnability Systems

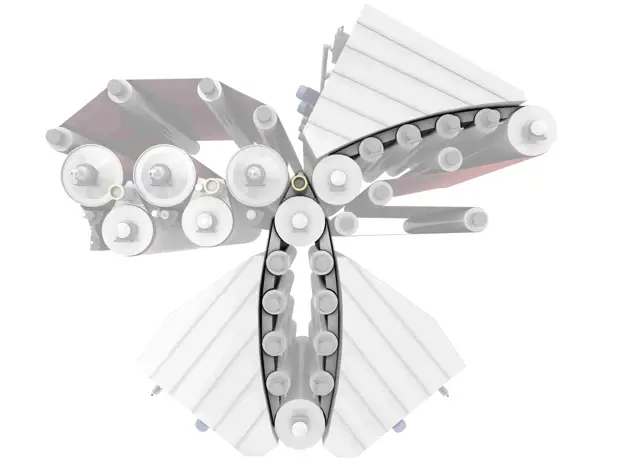

The two operating principles of runnability components are blowing and suction. Both types of equipment need the air system to provide blowing or suction air flow. A runnability component that operates by blowing functions as follows: Air is blown into the component and is ejected from a nozzle slot in the area between the component and the fabric. This creates underpressure and pulls the sheet against the fabric. There is no mechanical contact between the nozzle slot and the fabric. A runnability component that operates by suction creates underpressure by sucking air from the desired area. This area is sealed with cross-machine seals and side seals.

In OptiRun Single concept runnability components are used with an active vacuum suction roll like the Valmet Dryer Vac Roll. These together prevent the web from detaching from the dryer fabric in the single-fabric area.

Dryer section runnability - Hirun System

The Hirun runnability component creates a high vacuum space in the cross-machine opening nip to reduce stress on the sheet caused by the opening nip. Simultaneously, it prevents the sheet from detaching from the fabric when running by the roll toward the following dryer. A needed vacuum is created by blowing, suction, or a combination of both.

Hirun System has solutions for all needs.

Our customers have achieved excellent results with Valmet Hirun System:

- 30% draw reduction from the press section

- Stable web run

- Machine speed increase

- Chemical pulp saving

- Filler amount increase

- 75% less breaks

Explore more!

Read more about Valmet's compact concept - a game changer for drying sections with Hirun Web Stabilizer Compact.

Read moreDryer section runnability - Conventional runnability systems

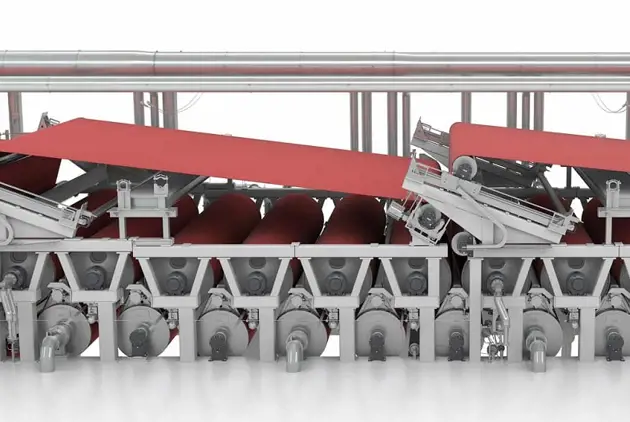

For a conventional dryer section, the runnability component creates underpressure under the fabric from the cylinder to the Vac Roll. The underpressure is developed by the nozzles and the suction effect of the Vac Roll.

OptiDry impingement dryer runnability system

Runnability System for OptiDry impingement dryers consists of Web Stabilizer OD and Web Stabilizer SR types of runnability components. Web Stabilizer OD is used with Vac Rolls, grooved fabric lead rolls and transfer suction rolls.

Air is blown from the nozzle slots at a high velocity, ejecting air from the area between the runnability components and the fabric. This creates underpressure and keeps the sheet in contact with the fabric while eliminating sheet flutter.

Press section runnability

Valmet Press Nip Web Stabilizer is installed before the separate press to prevent the detachment of the web from the press felt. Valmet Press Run Web Stabilizer is to support the sheet as fully as possible while it travels between the press and dryer sections.

The runnability components of the press section are usually equipped with four air blowing nozzle slots. Air is ejected from the nozzle slots at high velocity, causing underpressure in the space between the runnability components and the fabric. The pressure difference pulls the sheet against the fabric and eliminates all sheet flutter.

Do you want to know more about Valmet's compact concept?

OptiRun compact concept is a game-changer in paper machine dryer sections. Ensuring good runnability, improved drying efficiency and excellent tail threading, this is the biggest change in drying section design in the last 35 years.

Read the article

Do you want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsWatch the video about how to save energy with air systems

Drying is the most energy-intensive process of the paper machine and it can consume more than 80 % of the total thermal energy. A well-functioning hood, runnability system and heat recovery with air systems play a crucial role in energy efficiency and provide excellent opportunities for reducing costs and increasing profitability.

Explore our latest board and paper press releases

- Dec 8, 2025Valmet has completed change negotiations for temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Nov 26, 2025Valmet supports Wuzhou Special Paper’s transition to recycled board grades with a complete paper machine conversion rebuild

- Nov 5, 2025Valmet to start change negotiations regarding temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey