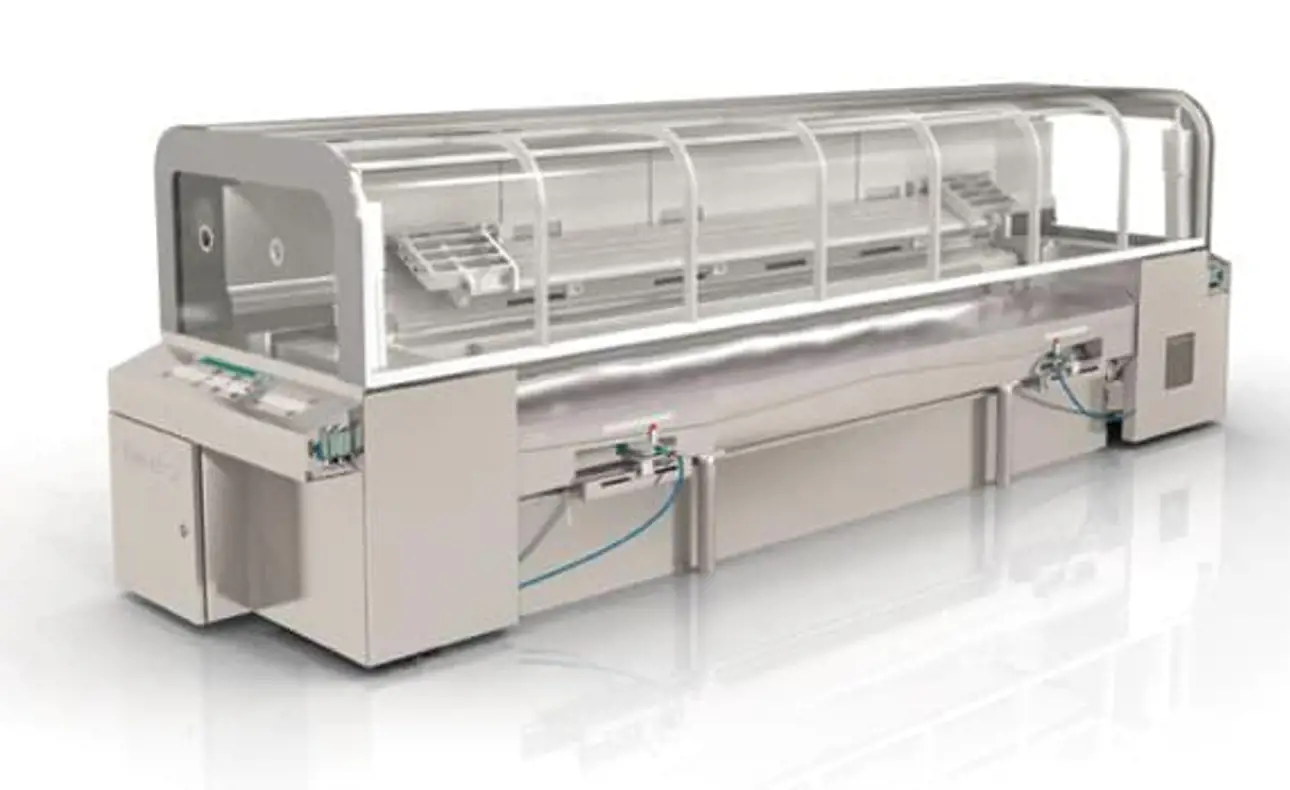

OptiCoat Layer curtain coating

Uniform layers simultaneously with one coating station

The OptiCoat Layer multilayer curtain coater applies extremely thin – or thick - and uniform layers simultaneously all within one, compact coating station. It is equally suitable for both board and paper machines, regardless of their speeds and widths. The multilayer concept offers several advantages over single-layer curtain coating and other conventional coating methods.

Flexible multilayer coating

Excellent printing properties

Easy to use

Low investment & operating costs

Flexible multilayer coating for thin functional layers

Curtain coating slide dye has an expandable design, which gives a possibility to upgrade the coating station by adding coating layers. The ability to coat both very thin and thick coating layers gives a possibility for a wide end product assortment. The fierce competition forces paper and board producers to rethink their processes and products.

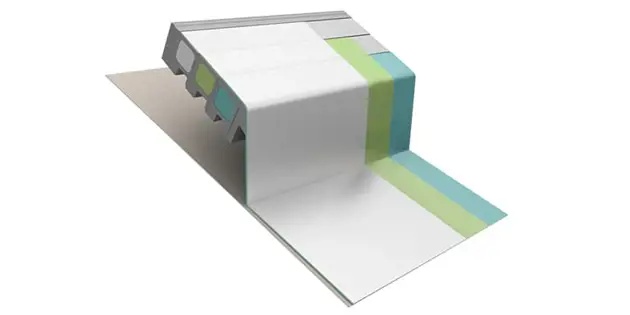

In multilayer coating, either one, two or even three layers can be applied. All the coating layers remain separate. This allows the use of functional layers, e.g. thermal or barrier coating colors. The thickness of a more expensive coating substance can be optimized, and a less expensive coating layer can function as carrier layer.

Want to talk to our coating experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts

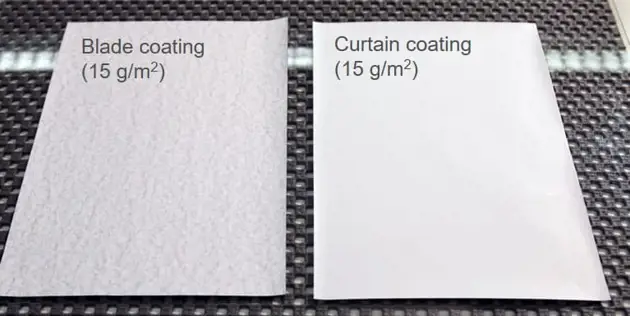

Excellent printing quality

OptiCoat Layer gives excellent profiles since the peak-to-peak coat weight variation is very low. There is no need for profiling; profiles are stable within a wide operation window. Due to an even coating thickness, coating layer has a uniform brightness. Even with lower coat weights, coating coverage is good, and total coating amount can be reduced.

Superior runnability and easy to use

Well-functioning air removal and fully sheltered coating process gives even and stable curtain coating. Excellent runnability and efficiency are the results from contactless coating method.

Low investment and operating cost

Because of the curtain coating method, the base paper can be produced with less or completely without white fibers. Each coating layer can be adjusted to desired function and cost. This enables the optimizing of the base paper and coating layer to reach the most cost-effective solution. There are no coating color losses because of the dry-edge running mode and careful recovery of the coating color. OptiCoat Layer curtain coating station is very compact in size and can easily be fitted in most paper or board machines.

Opportunities with different paper or board grades

With its numerous features, OptiCoat Layer brings a number of grade development possibilities. For coated white top testliners, there is a possibility to produce with less or no white fibers. For white lined chipboard, there is a possibility to reduce white fibers on top layer. Expensive ingredients in coating color can be minimized, and there can be an additional layer with protective function.

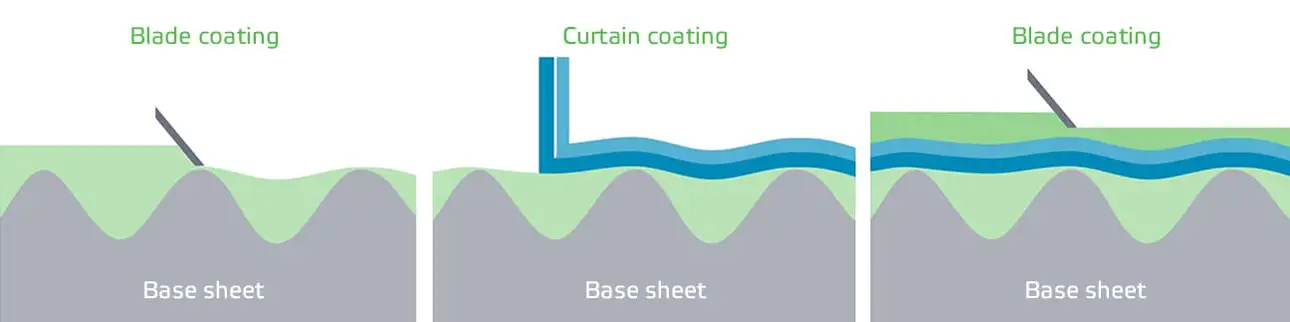

Blade coating + curtain coating + blade coating

One of the most interesting ways to use curtain coating is to first apply a blade coating layer, the the curtain coating in the middle, and again a blade coating layer. This brings out the best features of both coating methods. The uniform coating layers and good coverage of curtain coating combined with the smooth surface of blade coating gives excellent results. Furthermore, the profiles are stable and even in curtain coating.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookLearn more about the services and automation solutions for coating

Explore our latest board and paper press releases

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States