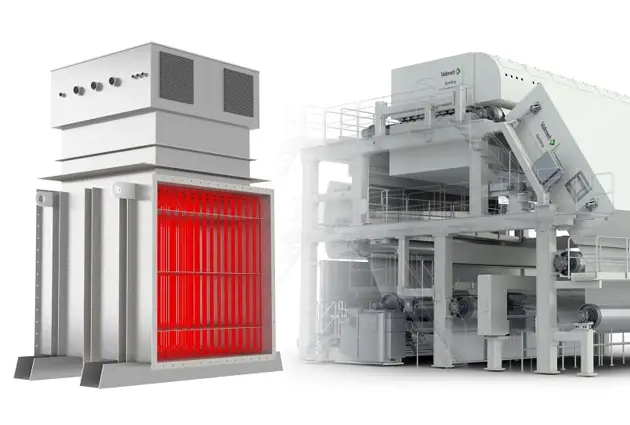

OptiDry Coat air dryers

Innovative, energy efficient air dryers for paper and board making

OptiDry Coat air dryers are designed for high drying capacity. Aided by patented air dryer nozzles, the dryers achieve uniform evaporation with minimum energy consumption, high efficiency and excellent runnability. We can prove you get the best paper quality and lowest energy consumption with Valmet air dryers.

Energy savings

Less maintenance costs

Better paper quality

High drying capacity

Coating drying is very energy demanding process and with air dryers it is possible to cut to half the energy costs of it. The energy efficiency of Valmet air dryers ranges from 70 to 80% and respectively the energy efficiency of infrared dryers only from 25 to 35%. So energy savings with air drying are 50% or more compared to infrared drying. The OptiDry Coat air dryers are high efficiency coating dryers for all coated paper and board grades. They can be used for both, new machines and rebuilds.

There are basically two kind of OptiDry Coat air dryers with several applications:

- OptiDry Coat high intensity, energy efficient air dryer for replacing IR dryers.

- OptiDry Coat air dryers for all the coating drying. Several applications with heating and layout.

Drying with OptiDry air dryers gives excellent:

- energy efficiency

- drying capacity

- end product quality

- runnability along with

- easy and low cost maintenance

- better working environment

- less fire hazard

- environmentally friendly approach

OptiDry Coat high intensity air dryer is suitable for positions where there earlier have been only IR dryers. We have several running paper and board machine references to support this statement. Start saving your energy costs with OptiDry air drying family and PowerFloat nozzles.

Want to talk to our coating drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsReplacing gas with electricity

Many paper producers are looking for ways to eliminate the use of fossil fuels in their production. How can this be achieved in coating drying?

CO2-free coating drying is enabled by using electric heating. A gas burner can be replaced with an electric heater, which can save energy at the same time. When electric heating replaces a gas burner in an air dryer and the process is optimized, energy savings are typically around 10 percent.

Do you want to know more about the electrification of air dryers?

We have answered frequently asked questions about replacing gas with electricity and infra-red dryers with air dryers.

Check the Q&AExplore our latest board and paper press releases

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States