Upgrade your old air dryers to today's technology

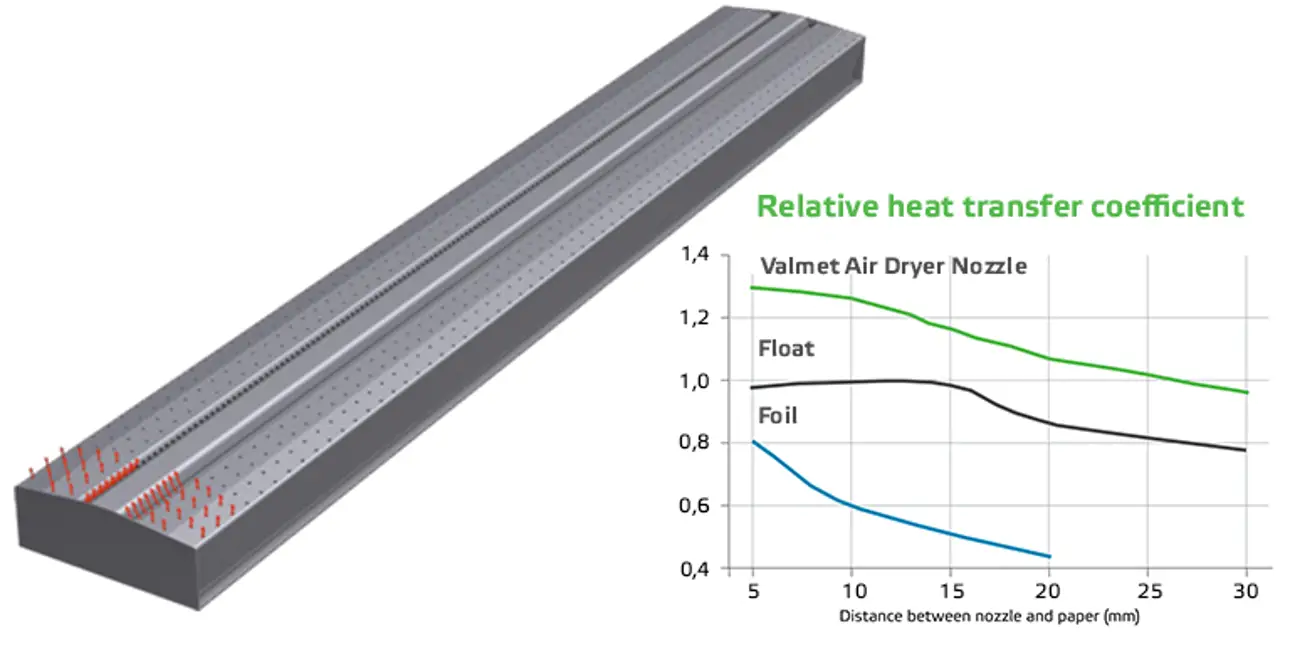

OptiDry air dryers are designed for high drying capacity. Aided by patented air dryer nozzles, the dryers achieve uniform evaporation with minimum energy consumption, high efficiency and excellent runnability. With these exceptional nozzles, it is possible to upgrade your old air dryers into new high evaporation, low energy consumption air dryers.

More drying capacity

Lower energy consumption

Low maintenance costs and need

Coating drying is a very energy-demanding process and with air dryers, it is possible to cut to half the energy costs. The energy efficiency of Valmet air dryers ranges from 70 to 90 % and respectively the energy efficiency of infrared dryers only from 30 to 40 %. So energy savings with air drying are 50 % or more compared to infrared drying. With new nozzles you get more drying capacity, better energy efficiency and runnability to old air dryers. Thus you can use less infrared dryers and get lower energy consumption in your coating machine. When transferring the drying from infrared dryers to air dryers with nozzle rebuild, the payback time is very short, in some cases, only a couple of weeks.

PowerFloat Profile nozzles for effective profiling with air

Now also available PowerFloat nozzles with profiling function. Valmet's new innovation is profiling air dryer OptiDry Profile, but you can also upgrade your old air dryers into profiling air dryers with PowerFloat Profile nozzles.

Start saving your energy costs with OptiDry air drying family and PowerFloat nozzles.

Want to talk to our coating drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsExplore our latest board and paper press releases

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China