Energy efficient coating drying for superior paper quality

Valmet coating drying for board and paper machines

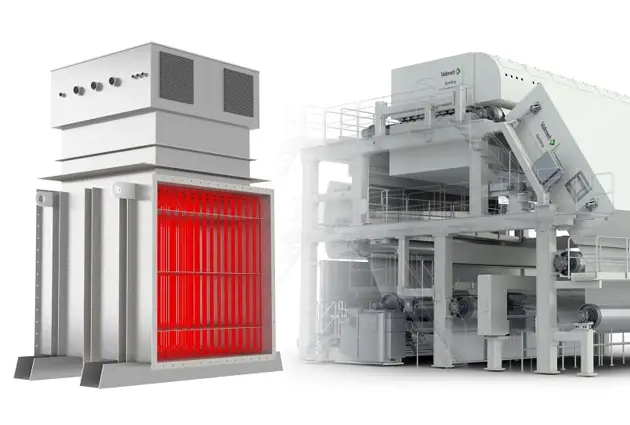

In modern coating machines all the coating drying is done with air dryers. We can prove to you to get the best paper quality and lowest energy consumption with Valmet air dryers. Economical and ecological air dryers can fulfill all the requirements for higher paper quality, lower production costs and improved runnability. Valmet's coating dryer selection offers energy efficient drying solutions for all kinds of coating drying needs.

Air drying is an energy-efficient solution for all coating drying

Thanks to high drying rates and effective nozzle technology, air dryers can achieve energy efficiency of up to 80%. Energy savings are 50% compared to infra-red drying since the energy efficiency of infra-red drying is much lower, only 25-35%, which means higher energy consumption and more costs. Air dryers are also environmentally friendly -50% less fuel is burned and CO2 is produced.

In addition, air dryers require much less maintenance time and costs and offer higher evaporation capacity. The maintenance savings are remarkable since there is no need to replace IR bulbs or emitters regularly.

Start saving your energy costs with the OptiDry air drying family and PowerFloat nozzles!

Want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsReplacing gas with electricity

Many paper producers are looking for ways to eliminate the use of fossil fuels in their production. How can this be achieved in coating drying?

CO2-free coating drying is enabled by using electric heating. A gas burner can be replaced with an electric heater, which can save energy at the same time. When electric heating replaces a gas burner in an air dryer and the process is optimized, energy savings are typically around 10 percent.

Do you want to know more about the electrification of air dryers?

We have answered frequently asked questions about replacing gas with electricity and infra-red dryers with air dryers.

Check the Q&AInterested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookExplore our latest board and paper press releases

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China