Increase pulp yield and lower costs

Valmet High Yield Pulping Optimizer

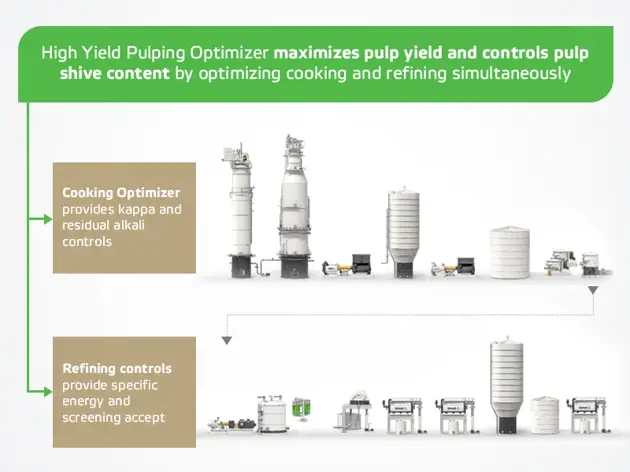

Valmet High Yield Pulping Optimizer intelligently coordinates cooking and refining processes to boost yield and production capacity at target quality.

30% reduction in pulp shive variability

0.5% increase in pulp yield

Over 1.5 million euros in potential raw material savings

Up to 3.5 million euros of more production capacity

The world’s first advanced process control for both cooking and refining, Valmet High Yield Optimizer helps pulp mills remain competitive in a rapidly evolving market. The optimizer is suitable for all types of chemical brown pulp producers.

From conservative targets to best performance

Many pulp mills have well-controlled cooking and refining processes, but these two departments are controlled independently. Without automatic coordination of cooking and refining, mill operators need to set conservative targets to avoid process upsets.

Suboptimum cooking and refining targets help avoid production disturbances, but this also leads to waste. For example, keeping digester Kappa target low to not overwhelm refining means wood consumption is higher than it would be if operations were fully optimized. Pulp mills miss out on their real production potential because cooking yield is not optimized against actual refining capacity.

Valmet High Yield Pulping Optimizer pushes existing equipment to the limits, getting the most out of every unit of input. Using advanced Model Predictive Control (MPC), the optimizer calculates future outcomes. Based on these predictions, it intelligently orchestrates automated control actions to operate cooking at the maximum Kappa target while keeping pulp shives on target in the refining process.

Orchestrating high yield

Valmet High Yield Pulping Optimizer brings entirely new opportunities for pulp mills to stabilize processes across departments and unlock maximum potential. This is achieved through a layered approach to the automation solution which supports the predictive modelling of the High Yield Pulping Optimizer.

Kappa and shive indexes are tracked through real-time measurements from the Valmet Brown Stock Analyzer. Kappa and shives are continually maximized against refining and screening capacity based on the hot stock refining control. The control provides the mechanisms for the High Yield Optimizer to set targets for specific energy and specific reject ratio targets that keep shive content at the maximum refiner limit. If there is room to increase the shive amount, the control automatically sets higher Kappa and shive targets for the digester. Valmet Batch Cooking Optimizer or Continuous Cooking Optimizer, part of the control solution, then adjusts cooking parameters to achieve higher Kappa and to get the maximum yield from the digester.

Related analyzers and optimizers