Real-time slag monitoring for effective boiler cleaning

Valmet Slag Indexing

The key to achieving the greatest accuracy and efficiency of your boiler cleaning is to improve input quality. Whether sequenced, timed or managed by an intelligent soot blowing system, the Valmet Slag Indexing software application provides an innovative additional layer of control.

Simplify slag control - Easy-to-understand slag metric supports decision making

Optimize inputs - Track effectiveness of slag prevention chemicals and find best mix of burn materials

Better overall operation - Use live feed and historical data to understand clinker and tube behavior

Improve the quality of boiler input

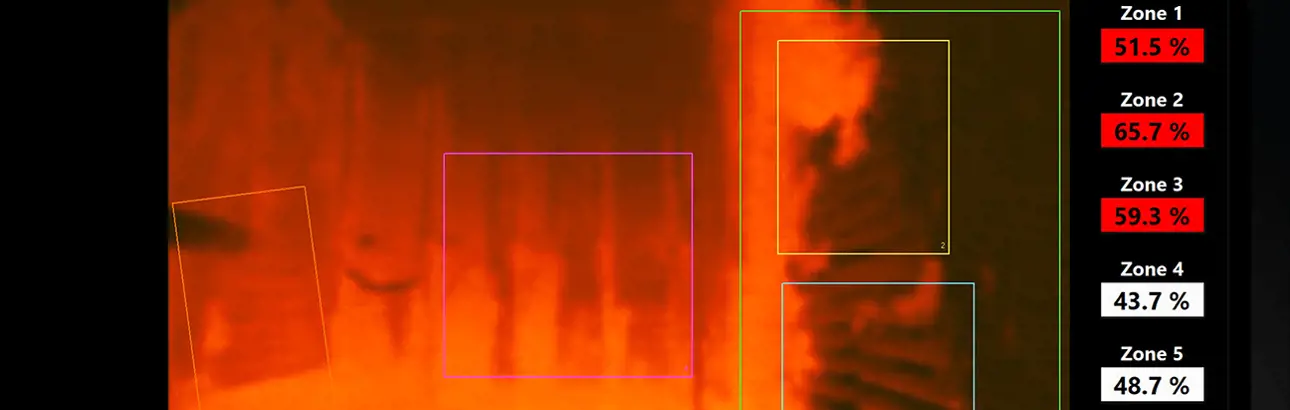

The Valmet Slag Indexing monitoring software provides an innovative and vital control mechanism for boiler operations. In real time, it precisely quantifies slag buildup in a given boiler view, and a full dashboard of live information gives you an immediate view of current boiler conditions as well as important historical data.

A simple, real-time slag metric

The Slag Indexing software calculates a real-time Slag Ratio. This precisely quantifies slag buildup in infrared camera view. From tube walls to pendants and the superheater entrance, Slag Indexing determines the ratio of a clean condition to a slagged condition. This condition ratio is then sent as an independent or added signal to the boiler cleaning controls to enable more effective cleaning of your boiler areas.

|

Benefits |

Features |

|

|