Improved production with Advantage ViscoNip press and ReDry

The Advantage™ ViscoNip® press and ReDry™ rebuilds at Sofidel’s tissue mills demonstrate benefits related to improved product quality, increased flexibility and machine runnability. In line with their multi-option strategy for reducing environmental footprint they also contribute to lower energy consumption.

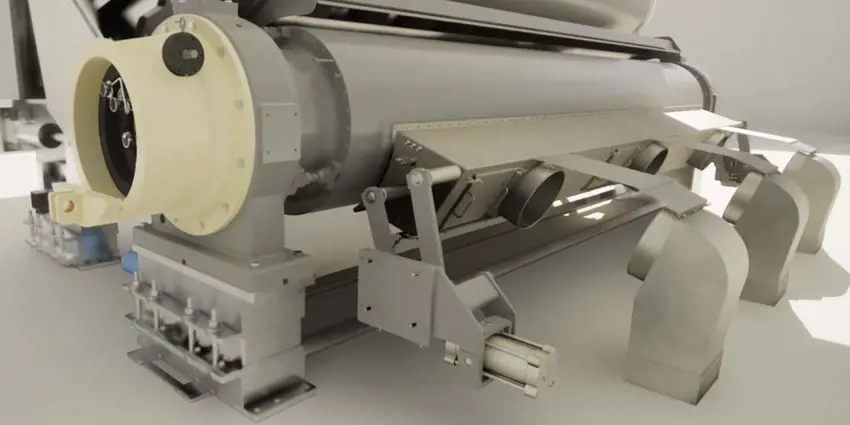

“In Baglan we replaced the suction press roll installed on the Advantage™ DCT 200 machine with a ViscoNip press and also added the ReDry. We have seen, after 5 months of running the machine, about 20% reduction of drying energy consumption even though we are still in the so-called learning curve phase. We have also experienced less web breaks; the paper that comes off the blade is more uniform. This was also noted immediately in the converting mill where they now have more stability in the sheet”

| Location | Sofidel Baglan, United Kingdom and Kisa, Sweden |

| Customer challenge | The customer reviewed components in the tissue machine to see where energy savings and production efficiency could be made as one action of achieving low-carbon economy. |

| Solution | Installed the Advantage ViscoNip press and the Advantage ReDry in two of their conventional tissue machines. |

| Result |

|

| Machine type | Conventional technology Valmet/other supplier |

We have seen an improved flexibility. Linear load and load ratio is easily changed during operation without any disturbance on the quality or runnability of the machine”.