Streamlining operations: Innovations in contaminant removal and automation

The ease of use for this equipment was what the mill really appreciated. I ensured everything was in place the day before start-up, and after two hours the unit was removing contaminants without any issues. In fact, it still is." - Michel Normadin, Product Manager, Screening, Valmet

South Eastern Canada

Despite being the first unit installed in region and within the corporation, the process proceeded smoothly, showcasing the reliability and performance of the equipment.

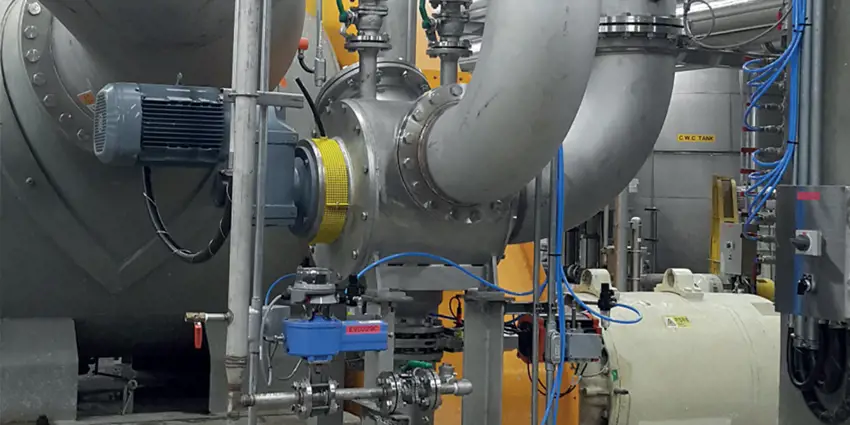

The implementation of Valmet Protection Screen DX at the Canadian pulp and paper mill exemplifies a successful collaboration between technology and industry expertise. By addressing critical challenges related to contamination management, Valmet's innovative solution not only enhanced operational efficiency but also set a benchmark for future installations within the corporation. Best of all, the lack of oversight means that operators can simply push a button and walk away, allowing for operators to focus on other projects.

Summary

| Location | Pulp mill in Southeastern Canada |

| Challenges | The mill faced challenges with contamination which led to frequent disruptions and equipment failures despite the presence of two magnetic traps. Inefficient cleanout mechanisms allowed metal pieces, pebbles, wood, and heavy plastic contaminants to bypass filtration, exacerbating issues like refiner plate failures and primary breakdowns. Manual purging by operators was ineffective leading to overload problems. |

| Solution |

Valmet Protection Screen DX |

| Results |

|

| Keywords | Contaminant removal, raw material efficiency, pulp mill |

Discover the Valmet Advantage

With over 225 years of industrial history, Valmet is the OEM partner you can trust. From unmatched process knowledge to comprehensive on-site services and training, we're here to support your success. Explore our resources and download the OEM guidebook today!