Minimizing deadload brings savings

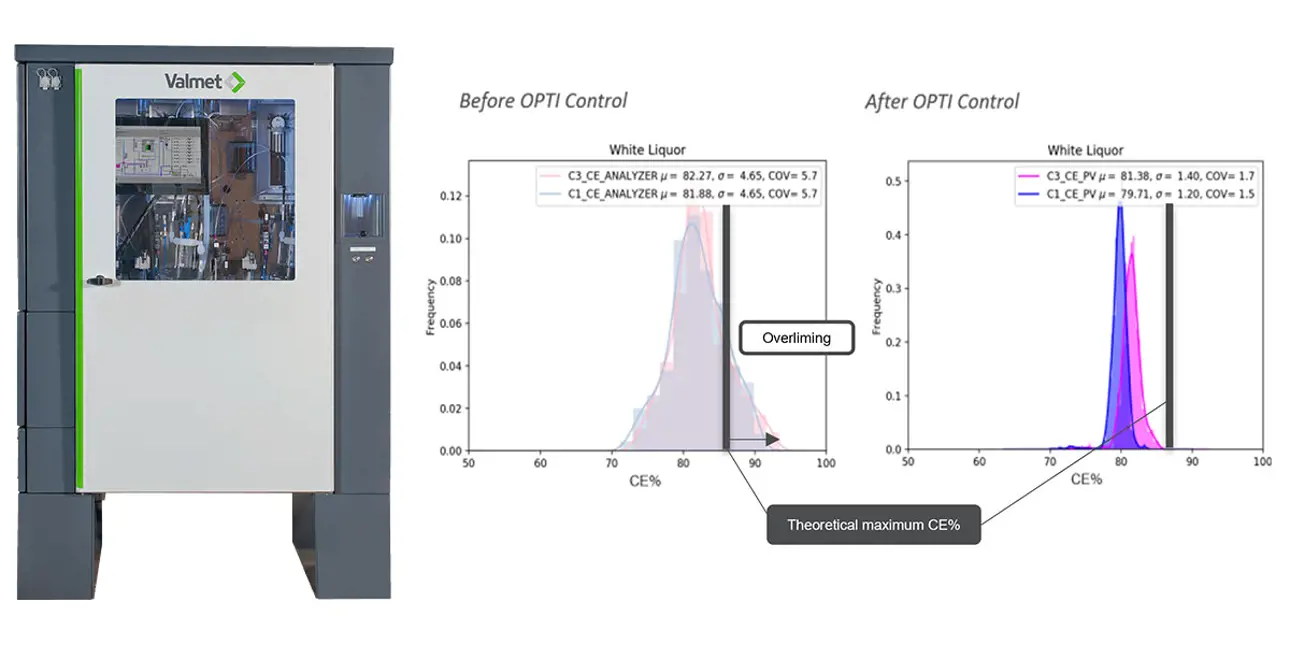

Kraft pulp mill in United States was able to eliminate overliming and reduce deadload with Valmet Recovery Liquor Analyzer (Valmet Alkali R) and Valmet Causticizing Optimizer with raw green liquor quality optimizer. Valmet's solution brings savings in chemical and energy costs.

“We wanted decrease variability of our green liquor TTA and white liquor CE% as well as increase the concentration of both variables. Valmet was able to eliminate overliming and reduce deadload in liquor cycle leading to significant chemical and energy savings.”

Summary

| Location | North America |

| Customer challenge |

|

| Solution |

|

| Results |

|

| Keywords | Pulping and fiber, North America, Automation |