Hanchang Paper Yangsan mill: Effective wax removal with Valmet Hydrocyclone

Hanchang Paper´s Yangsan mill in Korea chose Valmet Hydrocyclone SLP RC to improve the wax removal in their OCC line. Valmet´s technology was selected for its effectiveness in removing light weight rejects. Results showed significant reduction in wax, leading to fewer sheet breaks and zero wax-related claims.

Valmet Hydrocyclone SLP RC effectively removed most wax in the cleaning phase, leading to zero wax-related claims since its installation. We trust Valmet´s technology and greatly appreciate their expert support in optimizing our OCC process.

Summary

| Location | Yangsan, Korea |

| Solution |

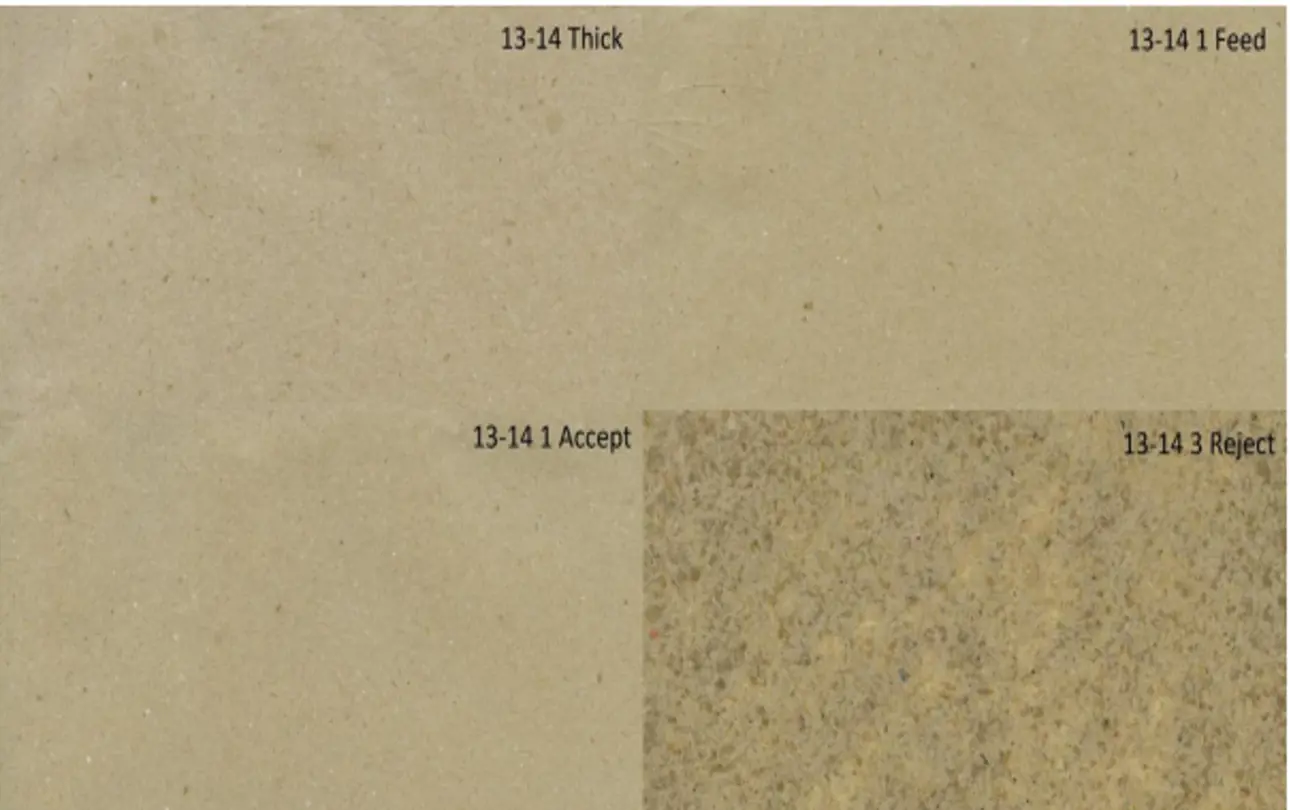

The Yangsan mill produces White Duplex board. The filler ply, with a capacity of 550 tons per day, does not use dispersion, and the wax content was creating hot melts bleeding through to the surface ply, leading to quality issues. Aim of the improvement was to remove wax from the final paper due quality issues. Valmet Hydrocyclone SLP RC was chosen for its effectiveness in removing light weight rejects, including wax, making it the ideal solution for the customer's needs. |

| Results |

There has been a significant reduction in wax, which has resulted in fewer sheet breaks and the elimination of wax-related claims. The process has been optimized, leading to improved performance and enhanced production efficiency. The impressive results demonstrated above clearly prove the effectiveness of the technology used for wax removal. |

| Keywords | Paper & board, Stock preparation, OCC, recycled fiber, improvements, hydrocyclone, cleaning, quality, Korea |