Beyond Circularity

Beyond Circularity is Valmet’s R&D program and ecosystem to transform waste and emissions into valuable resources for sustainable growth and accelerating the green transition.

Valmet's Beyond Circularity is an R&D program in which Valmet and its ecosystem come together to innovate, renew and enable their customer industries in the shift to carbon neutrality and to facilitate the green transition.

The Beyond Circularity Program aims to develop process technologies, automation and services to create value by utilizing renewable and recycled materials, industrial sidestream rejects and waste. Circularity is at the core of the program and its ecosystem, and its targets are closely connected to Valmet’s Technology vision 2035 and Climate Program – Forward to a carbon neutral future.

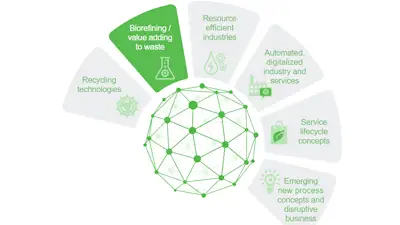

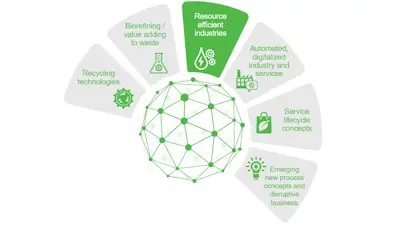

The program is implemented through seven streams: program management, recycling technologies; bio-refining/value adding to waste; resource-efficient industries; automated and digitalized industry and services; service life cycle concepts; emerging new process concepts and disruptive business.

A new green transition ecosystem is being built as part of this program. Working together within the ecosystem will create value and business for the participants, expand competences to new areas, and encourage the best national and international partners to join. The core of the ecosystem is Valmet’s unique triangular approach of technology, automation and services, enriched by the partners’ interdisciplinary expertise.

More than 310 partners have joined the ecosystem to work within 42 ecosystem projects. Internally Valmet has more than 90 program-related R&D projects ongoing or already finished.

On this image

-

1 Beyond Circularity: Developing innovative recycling technologies with ecosystem partners

-

2 Beyond Circularity: Turning biomaterials and waste into valuable products

-

3 Beyond Circularity: Maximizing efficiency and minimizing waste

-

4 Automated, digitalized industry and services

-

5 Service lifecycle concepts

-

6 Emerging new process concepts and disruptive business

Beyond Circularity: Developing innovative recycling technologies with ecosystem partners

In the Recycling technologies stream, we focus on developing recycling technologies across several areas. We’re actively working with textile, plastics and panelboard recycling, to mention some examples.

Beyond Circularity: Turning biomaterials and waste into valuable products

The target of the 'Biorefining / value adding to waste' stream is to develop technologies for turning biomaterials and waste into valuable products and replacing fossil-based raw materials. It's one of the streams in Beyond Circularity, Valmet's ambitious R&D program and ecosystem.

Beyond Circularity: Maximizing efficiency and minimizing waste

The 'Resource-efficient industries' stream aims to develop solutions for maximizing efficiency and minimizing waste. It's one of the streams in Valmet’s R&D program and ecosystem called Beyond Circularity.

Automated, digitalized industry and services

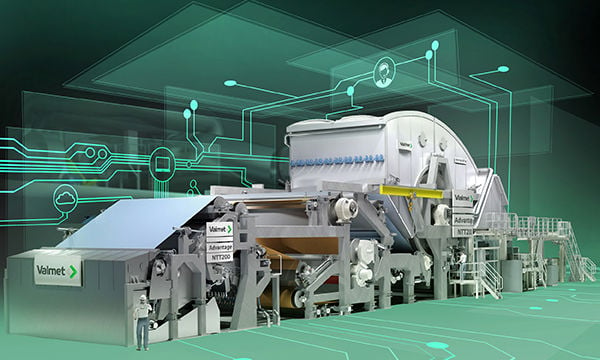

In the stream Automated, digitalized industry and services, the aim is to enable major leaps towards autonomous mills and safe processes, creating a thriving network with partners for developing energy saving and emission reducing services, and innovating novel process measurements for insight into the new processes developed within this Beyond circularity initiative.

Service lifecycle concepts

Within the Service lifecycle concepts stream, research is conducted on life cycle modelling for the technologies developed in the Beyond Circularity program.

Emerging new process concepts and disruptive business

The stream focuses on developing new processes for manufacturing of biochemicals, biofuels, 3D fibers etc. and investigating and piloting value chain (pilot and industrial scale technologies, business values, and partnerships) in e.g. food, medical and cosmetics.

Valmet plans to invest EUR 40 million in the Beyond Circularity Program between 2022 and 2025. The program is partly funded by Business Finland and is part of the “Veturi” initiative, which invites international companies to solve some of society’s most pressing challenges through increased research, development and innovation.

We are very excited about this program - all the new opportunities it will bring to us in Valmet, to our ecosystem partners, to our customers and to the entire globe by making green transition happen."

Recycling technologies

The Recycling technologies stream focuses on recycling technology development across several areas. These areas include processes for recycling preindustrial and post-consumer textile waste; new solutions for chemical recycling of plastics to enable circularity in petrochemical industry; development of resource efficient continuous panelboard recycling process; and creating readiness to integrate and offer together with partners carbon negative solutions for biorefining and energy industry.

Read more about the stream.

Ecosystem projects, which have received funding from Business Finland and EU:

- Co-innovation project HiPer – Fiber based composite materials to generate a completely new product portfolio based on lightweight, sustainable composite materials. These new materials will be suitable for several industrial sectors, such as construction, automotive, transportation, furniture, and packaging. Read more: the article and project’s web page. Watch also the video from the HiPer-project. (This project has ended)

- Co-innovation project UrbanFactory to elevate the recycling rates of challenging plastic waste streams through chemical recycling. Read more on VTT's release.

- Co-innovation project UrbanMill to develop an industrial chemical recycling concept for plastic waste. Read more on project's homepage. Read this article from VTT to learn about the project's results. (This project has ended)

- Co-research project SciSustain (Science translation framework for sustainable bioproducts innovation) to develop methods and tools on how bio-based processes can be scaled up to industrial levels from a holistic sustainability standpoint. Read more in the article on Aalto University's website.

- Co-research project Sustafit – Sustainable fit-for-purpose nonwovens. The nonwovens industry faces global and growing sustainability challenges that require a rapid transition to a circular economy. This project explored the sustainability of nonwovens from different perspectives to improve raw materials, processing methods, recyclability and business models.

- The project ended in September 2024. What did the project achieve? Read about the results on the release by Tampere University of Applied Sciences. Read also the article SUSTAFIT project shaped a roadmap for more sustainable future nonwovens aiming to boost the overall competitiveness of the Finnish nonwovens industry by ExpandFibre.

- One concrete result is the SUSTAFIT workbook "Sustainable Nonwovens of the Future – From Research Into Business Opportunities". It is designed to give insights on how to make products in the nonwovens industry more sustainable for the future

- Co-research project TexirC - Tackling textile circularity challenges. The project addresses four key challenges in textile recycling: colour stripping, fibre separation, compositional analysis, and de/repolymerization of the synthetics. Read more on the project page.

- PESCO-UP, a Horizon Europe project, funded by the European Union to transform the textile recycling industry by creating new raw materials from mixed wastes. Read more: the article and the project's web page. Watch also the video about the project.

Bio-refining / Value adding to waste

In the Bio-refining / Value adding to waste stream, bio-materials and waste are turned into products of value. One of the aims is to develop a new biomass pyrolysis solution to turn local sustainable feedstocks into global renewable transportation fuels and biochemicals. This stream also explores energy efficient continuous process to produce micro fibrillated cellulose for different applications and novel process solutions to turn ash waste and lignin into new products.

Read more about the stream.

Ecosystem projects, which have received funding from Business Finland and EU:

- Co-innovation project Bio4All aims turning forest and agricultural biomass residues into sustainable chemicals and fuels. Read more on VTT's press release and the blog post 'Fast pyrolysis of biomass as a tool for breaking free from crude oil by' Elmeri Pienihäkkinen and Juha Lehtonen.

- Co-innovation project BioBoost - Lignin fractionation for carbon and polymer applications. Read more about the project in VTT's newsletter.

- Co-innovation project CoCoBIN - Coating and converting of bio-based binders. Read more on University of Oulu's project page and on Clic's project page.

- Co-innovation project Non-wood raw materials

- Co-innovation project ReMatCh - Recycled material challenge

- Co-research project Depoly2ols to replace fossil-based aromatics in the chemical industry with innovative bio-based alternatives. Read more on Åbo Akademi University's press release.

- Co-research project GreenAro will develop sustainable production routes from renewable raw materials to aromatics needed in high volume for the production of products such as glues, paints and plastics. Read more about the project.

- Co-research project GROW - Growing sustainable bioproducts from industrial side streams)

- EU project REDYSIGN – Resource-efficient processes for the production and circularization of innovative recyclable-by-design fresh meat smart packaging from wood. Read more about the project and watch the video.

- The Clean Energy Transition Partnership (CETP) funded project LowCoBion. Read more about the project in its project page.

Resource efficient industries

The Resource efficient industries stream focuses on utilization of low energy heat lost from industrial processes through extended energy integration; research into new technologies to find more energy efficient solutions; closing of material loops in industrial processes to enhance material efficiency; using materials with high energy content as energy storage in industry as a part of smart electricity networks; and developing new, sustainable solutions for machine components.

Read more about the stream.

Ecosystem projects, which have received funding from Business Finland and EU

- Co-innovation project AMAze - Additive manufacturing postprocessing automation. Read more: DIMECC's press release.

- Co-innovation project CARAMEL – Circular processes and sustainable applications for novel hard metal coatings and structures

- Co-innovation project Resilient bronze

- Co-innovation project RheoMaTe aims to improve the processing of fiber-based biomaterials used e.g. in sustainable packaging, textiles, and composites. It develops precise rheological measurement methods and advanced material models to better capture their complex flow behavior. These models support new CFD tools for simulating flow in challenging conditions. Read more on the project page.

- Co-research project Data-driven design for sustainability. Read more on the project page (in Finnish).

- Co-research project Emission Free Pulping aims to significantly reduce biomass burning and increase the product yield of wood material used for pulping from approximately 50% to around 70%. Read more: the article about the project and project's web page. What happened in the first year of program? Read the Q&A with Program Coordinator Alina Ruonala-Lindgren.

- Co-research project IonMan - Ionized air lubrication for zero-emission manufacturing. Read more about the project in the release by University of Turku (in Finnish).

- Co-research project POWER Beyond – Process optimization with friction- and vibrationless technologies for energy efficiency and circularity. Read more about the project

- SteamDry, an EU-funded project revolutionizing the paper industry with superheated steam drying technology. Read the article about the project. Watch also the video to hear Harri Kiiskinen from VTT to discuss the project and its targets with Jyrki Huovila and Kalle-Matti Romppainen from Valmet. You will also hear comments from other project partners: Valerie Chauve from Ahlstrom, Joep Berghs from Sappi Maastricht BV, and Davide Mainardi from SOFIDEL S.p.A.

- ERDF program (EU consortium) Energy1st, energy-first fiber products forming. Read more on VTT's press release.

Automated, digitalized industry and services

In the stream Automated, digitalized industry and services, the aim is to enable major leaps towards autonomous mills and safe processes, creating a thriving network with partners for developing energy saving and emission reducing services, and innovating novel process measurements for insight into the new processes developed within this Beyond circularity initiative.

Read more about the stream.

Ecosystem projects, which have received funding from Business Finland and EU

- Co-innovation project BETTER - Beyond traditional roll service. Read more on the project page (in Finnish).

- Co-innovation project Biond4.0 – Data-driven control for bioprocesses

- Co-innovation project CTAC 2.0 - Cybersceurity assurance

- Co-innovation project USWA – Ultra scalable wireless access. Read more on project's home page.

- Co-innovation project Virtual Sea Trial. As modern ship designs become more complex due to stricter energy efficiency requirements and higher levels of autonomy, early simulation-aided testing is increasingly needed. The Virtual Sea Trial project aims to create a shared, distributed test environment for simulated system integration testing. The main development topics are commissioning interfaces, benefits realization, and test-driven design and commissioning. Read more on project's home page.

- Co-research project CEBIPRO – New analysis technologies for circular economy biorefineries. Read more about the project. This project has ended.

- Co-research project Hydrogen UnderGround (HUG) focusing on underground storage of hydrogen. Read more about the project. Watch also the video to hear Heikki Lindfors from Finnish Energy, Jaana Viitakangas from Helen, Jaakko Vuopio from AFRY and Valtteri Mustonen from Valmet discuss the project, its targets, and the significance of large-scale green hydrogen storage for the H2 value chain in general.

- Co-research project SEEDForest COACH creates steps towards human-focused, technologically enabled intelligent industrial work of the future. Read more about the project. This project has ended.

Service lifecycle concepts

Within the Service lifecycle concepts stream, research is conducted on life cycle modelling for the technologies developed in the Beyond Circularity program. Another focus area is development of lifecycle services concepts, taking into account critical indicators such as technical age, emissions, energy consumption, and water use.

Ecosystem projects, which have received funding from Business Finland and EU

- Co-innovation project EBITDA - Environmental and circular Business Impacts from value-chains: Tools for profitability and Desirability Analyses

- Co-innovation project L2C - Linear to circular through sustainable management approaches and data-driven business models. Read more about the project in Åbo Akademi University's release.

Read more about the stream.

Emerging new process concepts and disruptive business

The stream focuses on developing new processes for manufacturing of biochemicals, biofuels, 3D fibers etc. and investigating and piloting value chain (pilot and industrial scale technologies, business values, and partnerships) in e.g. food, medical and cosmetics.

Ecosystem projects, which have received funding from Business Finland and EU

- Co-research project CO2 capture

- Co-research project HYDROMAT - Towards the design of hydrogen-resistant material solutions - hydrogen diffusion, trapping, and inhibition in steel.

Explore some examples how the Beyond Circularity program enhances sustainability

Ecosystem

Business Finland partnership funding

Business Finland offers partnership funding for research, development, and innovation projects in leading companies' ecosystem themes. Our Finnish partners, whose joint projects have been accepted to Beyond Circularity ecosystem, may submit a partnership funding application to Business Finland.

Business Finland's cut-off dates for ecosystem funding applications in 2025

-

Co-innovation funding can be applied continuously throughout the year

-

The last possibility for applying co-research funding will close on August 29, 2025.

More information: Business Finland website and beyondcircularity[at]valmet.com

Contacts

Contact us at beyondcircularity(at)valmet.com.

Viivi Villa-Nuottajärvi

VP, Research & Development

Valmet

Marke Kallio

Director, R&D programs

Valmet

Virpi Puhakka

Director, Ecosystem

Valmet

Kari Koskela

Valmet Veturi lead

kari.koskela(at)businessfinland.fi

Business Finland

Related pages