Shoe press case study - Using nip scan as pre-shutdown tool

A mill had issues widening the sheet after threading the machine. Valmet performed a nip scan to collect information about loading and alignment problems.

Insights ● ArticleFilters

Shoe press case study - Using nip scan as pre-shutdown tool

A mill had issues widening the sheet after threading the machine. Valmet performed a nip scan to collect information about loading and alignment problems.

Insights ● Article

Maximize performance with Valmet's modular service solutions

Valmet's modular service solutions offer pulp and papermakers clearer choices for the maintenance of rolls and equipment for fiber production. This helps the customer to make wise maintenance choices, for efficiency and maximum performance.

Insights ● Article

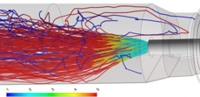

Increase drying capacity with a Valmet Air Dryer Nozzle Upgrade

Existing single- or double-sided air dryers with inefficient nozzles can be upgraded by installing the patented Valmet Air Dryer Nozzle Upgrade - without changing your dryer layout. Up to a 50% drying capacity increase can be realized.

Insights ● Article

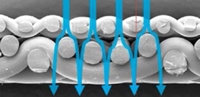

Polarized forming fabrics may revolutionize water removal

The polarized structure allows controlled initial drainage in the paper-making process, improving retention and helping keep the machine clean. The good runnability and cleanliness reduce breaks, increasing production capacity and saving through reduced use of chemicals.

Insights ● Article

Valmet Refiner Segments - there is always a higher level

Are there limits to refiner segment technology? We optimize processes and stabilize them at the highest attainable and sustainable level. Some engineers might feel satisfied at this point, but at Valmet we don’t.

Insights ● Article

ServoNavitas - your toolbox for refiner segment technology

Refining is the key process when producing both mechanical pulp and fiberboard. Valmet continuously develops refiner segment technology to improve customer competitiveness. As a result of this development we present a new unidirectional segment concept called ServoNavitas.

Insights ● Article

Using wood powder as fuel in lime kilns, pilot case study

A Valmet white paper discusses the use of wood powder as a replacement lime kiln fuel, as well as the factors that must be considered when evaluating using wood powder as kiln fuel and the lessons learned from operating with wood powder. Södra has contributed to this paper based on their experience at Södra Värö mill with a wood powder firing system that was installed in 2014.

Insights ● Article

Valmet polarized forming fabrics give great results, case studies

Customer experiences have shown that Valmet's polarized forming fabrics have the potential to revolutionize water removal in the papermaking process. Two board machine case studies illustrate the savings that are possible.

Insights ● Article

Valmet intelligent roll solutions for tissue lines (webinar)

Case studies include press nip profiles, measuring sheet temperature, loose sheet edges/bagginess, parent roll hardness and optimizing reels and rewinders.

Insights ● Article

Flow control partner spotlight: IBEJ

Channel partners provide a valuable community to support Valmet's flow control customers all over the world. We interviewed one of our newest Valmet partner community members, IBEJ, from Bosnia to describe their daily work and projects. They were recently awarded as the Best new partner at the European Distributor Days 2023. Read the interview with Dragan Čizmić, Executive Director at IBEJ, and watch the video.

Insights ● Article