Example pneumatic maintenance schedule - weekly, monthly, annual

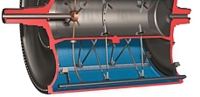

While pneumatic components and systems normally require very little maintenance, regular inspections with minor adjustments are important. This schedule and tips are intended as a guideline.

Insights ● Article